In genere, si utilizza la saldatura TIG per garantire saldature lisce e senza crepe. La saldatura diventa notevolmente più difficile e costosa quando lo spessore supera 1,5 mm.

2. Difficoltà nella piegatura e nella formaturaL'acciaio inossidabile con spessore superiore a 1,2 mm richiede una pressione maggiore e stampi più precisi durante la piegatura. Pertanto, uno spessore eccessivo aumenta le difficoltà di produzione e rende più difficile mantenere linee di bordo precise.3. Rettifica e lucidatura superficiale

Le piastre più spesse presentano una maggiore resistenza all'usura durante la rettifica, sono meno soggette a scolorimenti o a spazzolature irregolari e presentano una consistenza visivamente più fine. Tuttavia, uno spessore eccessivo aumenta i tempi e i costi di rettifica.

Come determinare correttamente lo spessore quando si acquista un lavello da cucina in acciaio inossidabile fatto a mano?

1. Controllare le specifiche del produttore

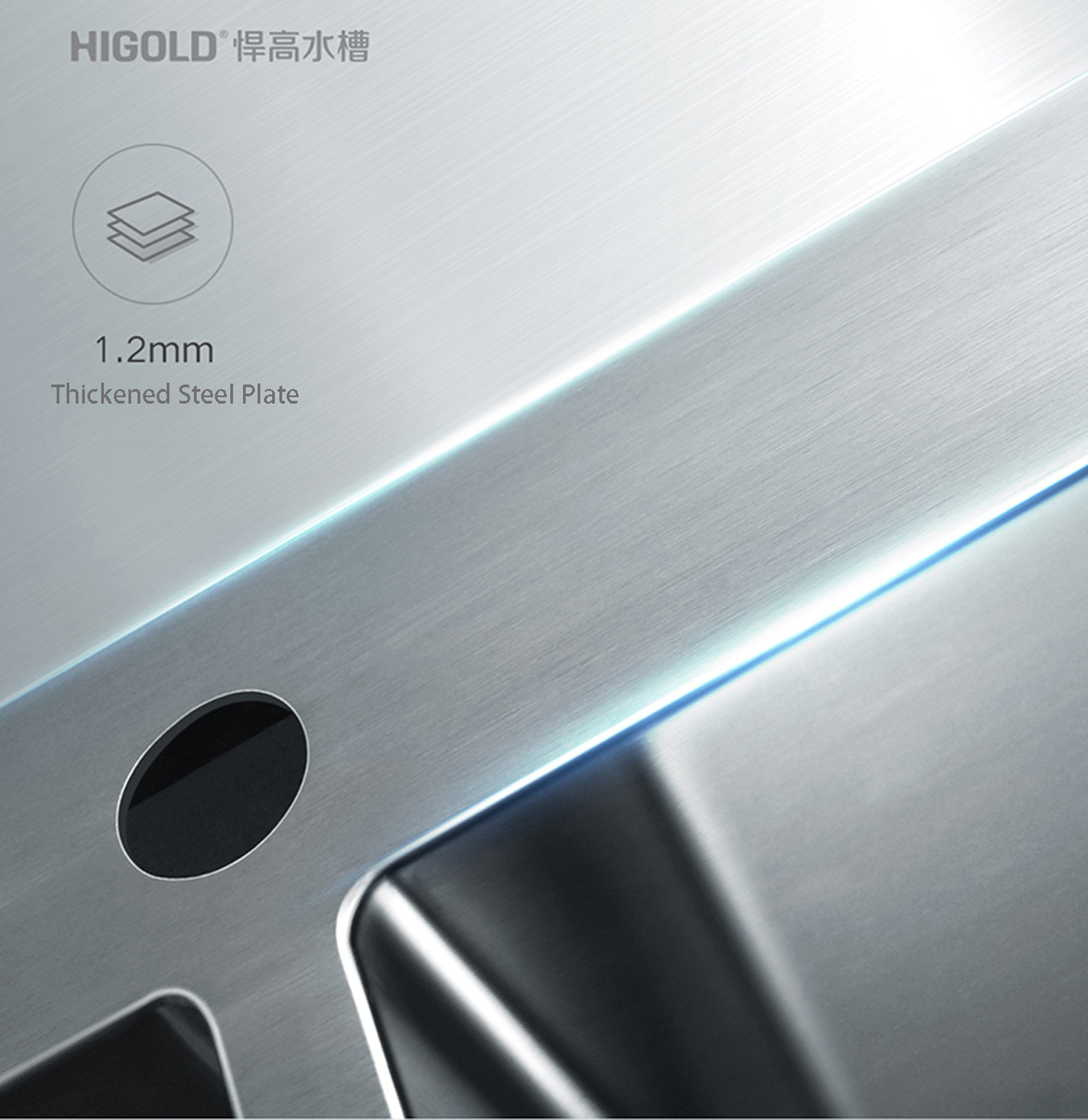

I marchi affidabili indicano chiaramente il materiale (ad esempio, SUS304) e lo spessore (ad esempio, 1,2 mm). Diffidate dei lavelli che riportano solo ""thickened"" senza specificare un valore.

2. Metodo di misurazione

È possibile misurare lo spessore del bordo utilizzando un calibro (si noti che le aree saldate potrebbero essere leggermente più spesse) per evitare di essere ingannati da etichette false. Ad esempio, alcuni prodotti hanno in realtà uno spessore di soli 0,8 mm ma sono pubblicizzati come lamiera da 1,2 mm.

3. Scelta dello spessore in base all'applicazione

• Lavello a vasca singola: si consiglia lo spessore di 1,2 mm per una maggiore resistenza agli urti.

• Lavello a doppia vasca: si consiglia 1,0 mm per un equilibrio tra peso e stabilità.

• Lavelli commerciali o di grande capacità: considerare uno spessore di 1,5 mm o superiore.

Oltre allo spessore, cos'altro dovresti considerare quando acquisti un lavello da cucina in acciaio inossidabile fatto a mano?

Lo spessore è importante, ma non è l'unico parametro per valutare la qualità di un lavello. Anche i seguenti fattori influenzano l'esperienza d'uso:

• Purezza del materiale: deve essere acciaio inossidabile 304 o 316 autentico;

• Finitura superficiale: i trattamenti spazzolati, opachi e anti-impronta determinano l'attrattiva estetica;

• Design inferiore: include cuscinetti ammortizzanti e un rivestimento anticondensa?

• Struttura di drenaggio: lo scarico è ispessito e gli accessori sono a prova di intasamento?

• Processo di saldatura: le saldature degli angoli sono lisce e prive di punti neri?

• Reputazione e garanzia del marchio: i produttori affidabili forniscono una garanzia di qualità più stabile.

In altre parole, lo spessore è solo uno degli indicatori più importanti; ciò che determina realmente l'esperienza dell'utente sono i dettagli completi di progettazione e produzione.

Higold fornisce garanzie sui prodotti?

Sì, tutti i lavelli e i rubinetti Higold sono coperti da rigorosi controlli di qualità e garanzie di fabbrica. I nostri prodotti vengono testati per soddisfare gli standard globali prima della spedizione. Gli acquirenti possono acquistare all'ingrosso in tutta sicurezza, sapendo che la nostra azienda offre un servizio post-vendita e un supporto costante. Ordinando prodotti ODM, i clienti beneficiano anche di garanzie personalizzate legate ai loro specifici progetti.

Different brands, intended uses, and installation requirements will result in slight variations in thickness. The following are common thickness ranges and characteristics:

Thickness (mm) | Features | Applicable Situations |

| 0.8mm | Thinner, low price, easily deformed | Economy products, lightly used kitchens |

| 1.0mm | Standard thickness, high cost-performance ratio | Most family kitchens |

| 1.2mm | High-end thickness, structurally stable | Mainstream thickness for hand-welded sinks |

| 1.5mm | Extra-thick type, strong impact resistance | Commercial kitchens, large sink designs |

As can be seen, 1.0-1.2mm is the optimal thickness range for household use. While sheets thicker than 1.5mm are sturdier, they are more expensive, more difficult to process, and have limited practical value.

Is thicker always better for handcrafted stainless steel kitchen sinks?

1. From a structural perspective: There is an upper limit to thickness increases

Moderately increasing the thickness can indeed enhance the stability and lifespan of the sink. However, beyond a certain range (such as exceeding 1.5mm), the benefits diminish significantly. For example:

• Limited increase in strength from thicker sinks;

• Significantly increased weight, making installation more difficult;

• Increased cost, but little improvement in daily user experience.

Therefore, "thicker is always better" is not scientifically sound; rather, the intended use, installation method, and overall balance must be considered.

2. From a sound control perspective: Thickness isn't the only factor

While thickness can improve noise levels, the addition of shock-absorbing and sound-dampening pads is more crucial. Many high-end handcrafted stainless steel kitchen sinks with a thickness of 1.0mm still achieve good noise reduction through the combination of bottom shock-absorbing pads and anti-condensation coatings.

3. From a user experience perspective: Excessive thickness reduces elasticity

An excessively thick stainless steel surface lacks resilience when impacted with objects, making it feel stiffer when washing dishes and more prone to cracking ceramic tableware. This is a "hidden side effect" of excessive thickness.

The impact of Thickness on Stainless Steel Material Performance

1. The thickness difference between 304 and 316 stainless steel

Handcrafted stainless steel kitchen sinks commonly use 304 stainless steel (containing 8% nickel and 18% chromium), which has good rust and corrosion resistance. Some high-end sinks use 316 stainless steel, which has stronger resistance to acids and alkalis.

Because 316 has slightly higher strength, under the same structural conditions, 316 material can be used at a slightly thinner thickness (e.g., 1.0mm) while still maintaining sufficient rigidity.

2. Relationship between Thickness and Surface Finish

Thicker stainless steel is better suited for high-end surface finishes such as brushing and sandblasting, maintaining a smooth surface and resisting deformation. Conversely, thinner sheets are prone to ripples or uneven reflections during surface processing, affecting aesthetics.

3. Thickness Has No Direct Relationship with Corrosion Resistance

Thickness does not determine rust resistance. Corrosion resistance mainly relies on the formation of a passivation film (chromium oxide layer) on the stainless steel surface. As long as the material is qualified, the rust resistance of 0.8mm and 1.2mm is essentially the same.

What are the Pros and Cons of different thicknesses of handmade stainless steel kitchen sinks?

Thickness range | Advantages | Disadvantages |

| Below 0.8mm | Affordable price, lightweight | Prone to deformation, high noise, low weld strength |

| Around 1.0mm | High cost-performance ratio, sturdy and durable | Requires high welding skills |

| 1.2mm | Excellent stability, high-end appearance | Slightly higher cost, increased weight |

| Above 1.5mm | Extremely strong structure, virtually vibration-free | High cost, inconvenient installation, exceeds household needs |

For most families, a thickness of 1.0–1.2mm is ideal for handmade stainless steel kitchen sinks, ensuring structural strength while also considering comfort and ease of installation.

How well does the thickness of handmade stainless steel kitchen sinks match the manufacturing process?

1. Relationship between Welding Quality and Thickness

The thicker the sheet, the deeper the weld, and the higher the requirements for welding heat control. High-quality handmade stainless steel kitchen sinks typically employ TIG welding to ensure smooth, crack-free welds. Welding becomes significantly more difficult and costly when the thickness exceeds 1.5mm.

2. Difficulty in Bending and Forming

Stainless steel thicker than 1.2mm requires greater pressure and more precise molds during bending. Therefore, excessive thickness increases manufacturing difficulty and makes it harder to maintain precise edge lines.

3. Surface Grinding and Polishing

Thicker plates exhibit stronger wear resistance during grinding, are less prone to "blueing" or uneven brushing, and have a finer visual texture. However, excessive thickness increases grinding time and cost.

How to Correctly Determine the Thickness When Purchasing a Handmade Stainless Steel Kitchen Sink?

1. Check the Manufacturer's Specifications

Reputable brands will clearly indicate the material (e.g., SUS304) and thickness (e.g., 1.2mm). Be wary of sinks that only state "thickened" without specifying a value.

2. Measurement Method

You can measure the edge thickness using calipers (note that welded areas may be slightly thicker) to avoid being misled by false labeling. For example, some products are actually only 0.8mm thick but are advertised as "1.2mm sheet."

3. Choosing Thickness Based on Application

• Single-bowl sink: 1.2mm is recommended for strong impact resistance.

• Double-bowl sink: 1.0mm is recommended for a balance between weight and stability.

• Commercial or large-capacity sinks: Consider 1.5mm or thicker.

Besides thickness, what else should you consider when buying a handcrafted stainless steel kitchen sink?

Thickness is important, but it's not the only standard for evaluating sink quality. The following factors also affect the user experience:

• Material purity: Must be genuine 304 or 316 stainless steel;

• Surface finish: Brushed, matte, and fingerprint-resistant treatments determine the aesthetic appeal;

• Bottom design: Does it include shock-absorbing pads and an anti-condensation coating?

• Drainage structure: Is the drain outlet thickened, and are the accessories clog-proof?

• Welding process: Are the corner welds smooth and free of black spots?

• Brand reputation and warranty: Reputable manufacturers provide more stable quality assurance.

In other words, thickness is only one of the "hard indicators"; what truly determines the user experience is the comprehensive design and manufacturing details.

Does Higold provide product guarantees?

Yes, all Higold sinks and faucets are backed by strict quality control and factory warranties. Our products are tested to meet global standards before shipping. Buyers can purchase wholesale with confidence, knowing that our company provides after-sales service and consistent support. When ordering ODM products, customers also benefit from tailored guarantees linked to their specific designs.

Lavelli da cucina in acciaio inox di alta qualità fatti a mano